EFKO has commissioned the first stage of its desalination plant in Taman, Krasnodar Krai. The plant can produce up to 30 cubic metres of fresh water per hour. There are plans to increase this figure to 60.

Fresh water is one of the scarcest resources on Earth. It accounts for no more than 3% of all water on Earth. Most of it turns into groundwater, about a quarter, into ice and only the remainder accumulates in rivers, lakes and goes to meet the needs of 8 billion people: drinking, cooking and household use.

Peninsulas particularly face an acute shortage of fresh water. EFKO knows this from experience at its Taman manufacturing site.

The network of water pipelines on the peninsula is designed only to cater for the needs of local residents and not industrial facilities. Therefore, the network was often stretched to the limit, especially at the peak of the tourist season. Coupled with wear and tear, high loads on networks raise the risk of breakdowns and water shortages.

To mitigate possible tension, EFKO took a leaf from countries that have successfully dealt with this challenge – the UAE, Israel, Algeria, Kuwait etc – and built its own desalination plant.

This will prevent water supply disruptions and ease the load on local municipal networks. According to Valery Ruzhitsky, a deputy of the municipal council of the Temryuk District, this is one of the most promising solutions to the shortage of fresh water on the peninsula.

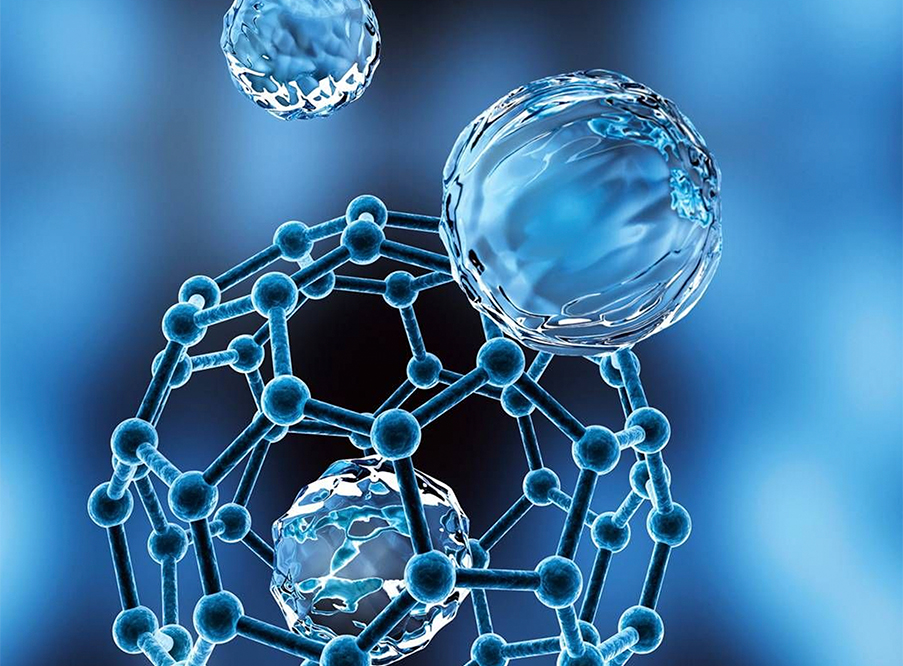

The plant's operating principle is simple: excess salt and impurities are extracted from the salty seawater entering the plant under pressure using reverse osmosis. The obtained fresh water is used to meet the company's needs.

The Taman site has been implementing zero discharge technology since 2009. It ensures the most economical water consumption, including the collection and use of all resources – from treated wastewater to rainwater. Desalinated seawater will account for about 40% of the water used at the site. This will free up part of the public utilities to meet the needs of the residents of the peninsula.

The first stage of the project took three years to complete. The equipment cost 100 million rubles. The plant was built in strict compliance with environmental laws.

The Taman marine terminal is one of Russia's largest specialised terminals for the transhipment of liquid food cargo. It can handle ships with a deadweight of up to 55,000 tonnes. The tank farm has a capacity of 190,000 tonnes. In 2021 the port's transhipment volume was 1,600 million tonnes of cargo.